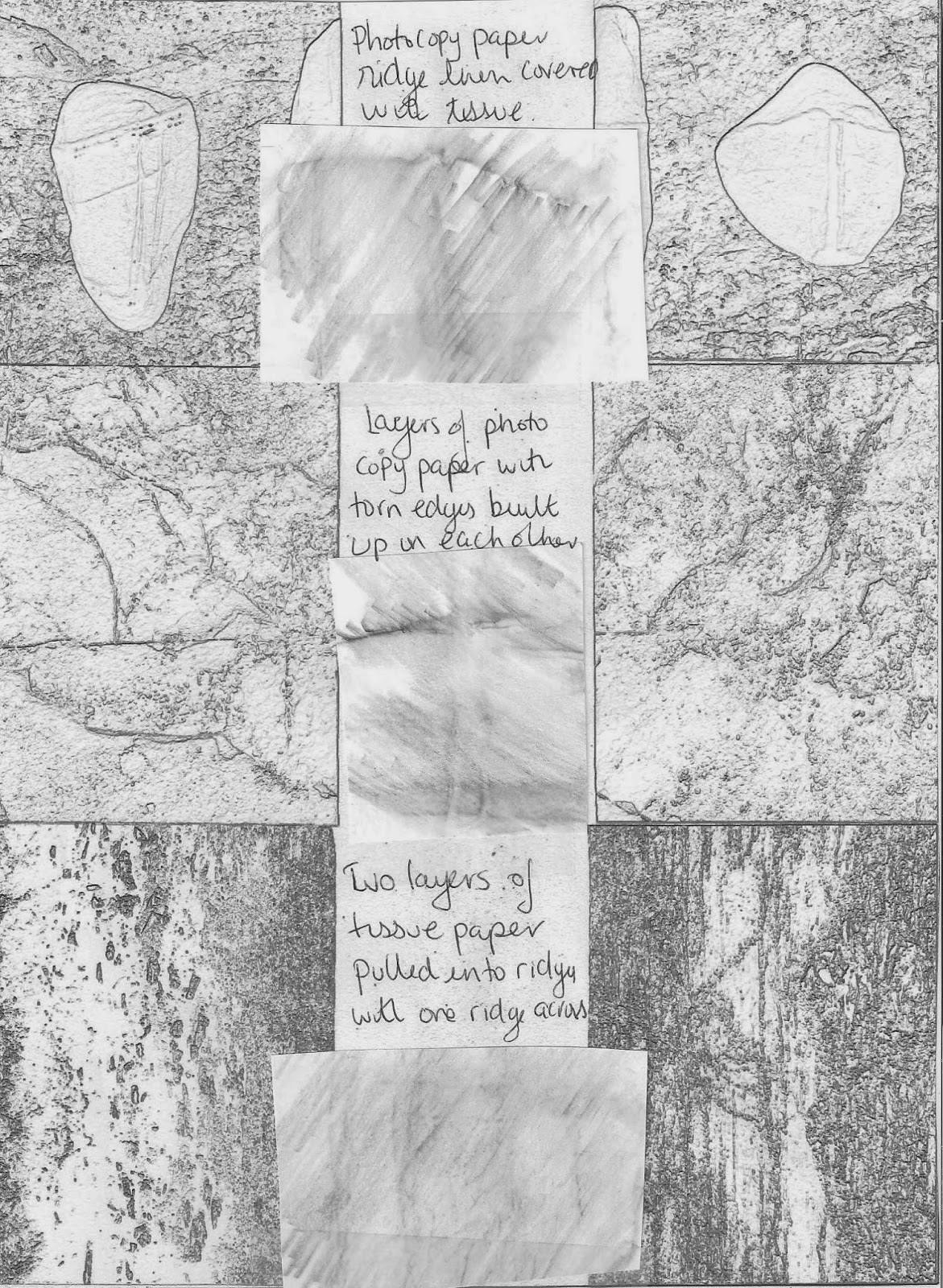

Grouping the materials in fabric type small pieces of fabric were placed on grid prior to seeing how they performed in later experiments. A record was kept on the fabrics and its characteristics and these are recorded beside the description.

COTTON

|

| Ref 5.4.1a |

A. muslin - a loose open weave fabric that frays and can be manipulated easily

B. cheesecloth - as with muslin but not so easily frayed

C. printed voile - a close weave with a soft handle that takes printed detail well

D. light weight calico - a cross between cheesecloth and voile with thicker yarns

E. scoured calico - a closer weave than D but similar weight of yarn

F. calico - a closer weave that gives a clear weave pattern

G. lawn - lightweight smooth fabric with see through quality

H. percale - close weave with smooth feel

I. printed cotton- more pronounced weave pattern than percale takes a print well

J. printed calico - a lighter weight than

K. poplin - a smooth but very close weave that takes digital prints well

Natural

A. Linen natural - a firm even weave fabric that is used for embroidery

B. Linen bleached - a bleached and more open version of A

C. Jute hessian - rough open weave with slubby yarns

D. Jute scrim - very open flexible weave

|

| Ref 5.4.1b |

E. Linen natural fine weave - a closer weave which gives a a lovely fluffy fray

SILK

A. Noil natural - a slubby open weave 'rounded' fabric

B. Organza - a sheer close weave with fine yarns

C. Natural silk - even weave fine yarn with little lustre

D. Light dupon - a sheen but not slubby fabric

E. Habotai - lustre and fine weave

F. Sari ribbons - fine weave with slubs and remnants of different weights

G. Throwster silk ends - a compact rod that pulls out into fibrous surface

|

| Ref 5.4.1c |

MANMADE

A. Felt - soft, surface with no visible weave and difficult to fray but fibres can be teased

B. Fleece- soft and more flexible than felt

C. Adhesive vilene - flexible fabric which can be pulled without losing shape, adhesive spots that melt on heat on one side

D. Polyester/viscose face wipe - soft malleable fabric

E. Tyvek - visible, soft but tough structure which belies its character when heated

F. Nylon lace - open weave and design which is flexible and decorative

G. Nylon - opaque, even weave with yarns that are long

H. Nylon organza - sheer open weave fabric with high sheen, soft and malleable

I. Jersey nylon - distinctive knitted surface which stretches

J. Lace * heat test seemed to proved this piece was in fact a natural fibre

K. Nets- different weights of net which don't fray but are malleable.

The task was to then take a closer look at the edges and see how to translate and explore the characteristic of the fabric into decorative edges. Looking again at the detail in my photos the ideas that came to mind were: jagged, soften, erode but before these I realised that the selvedges of the materials were in themselves interesting.

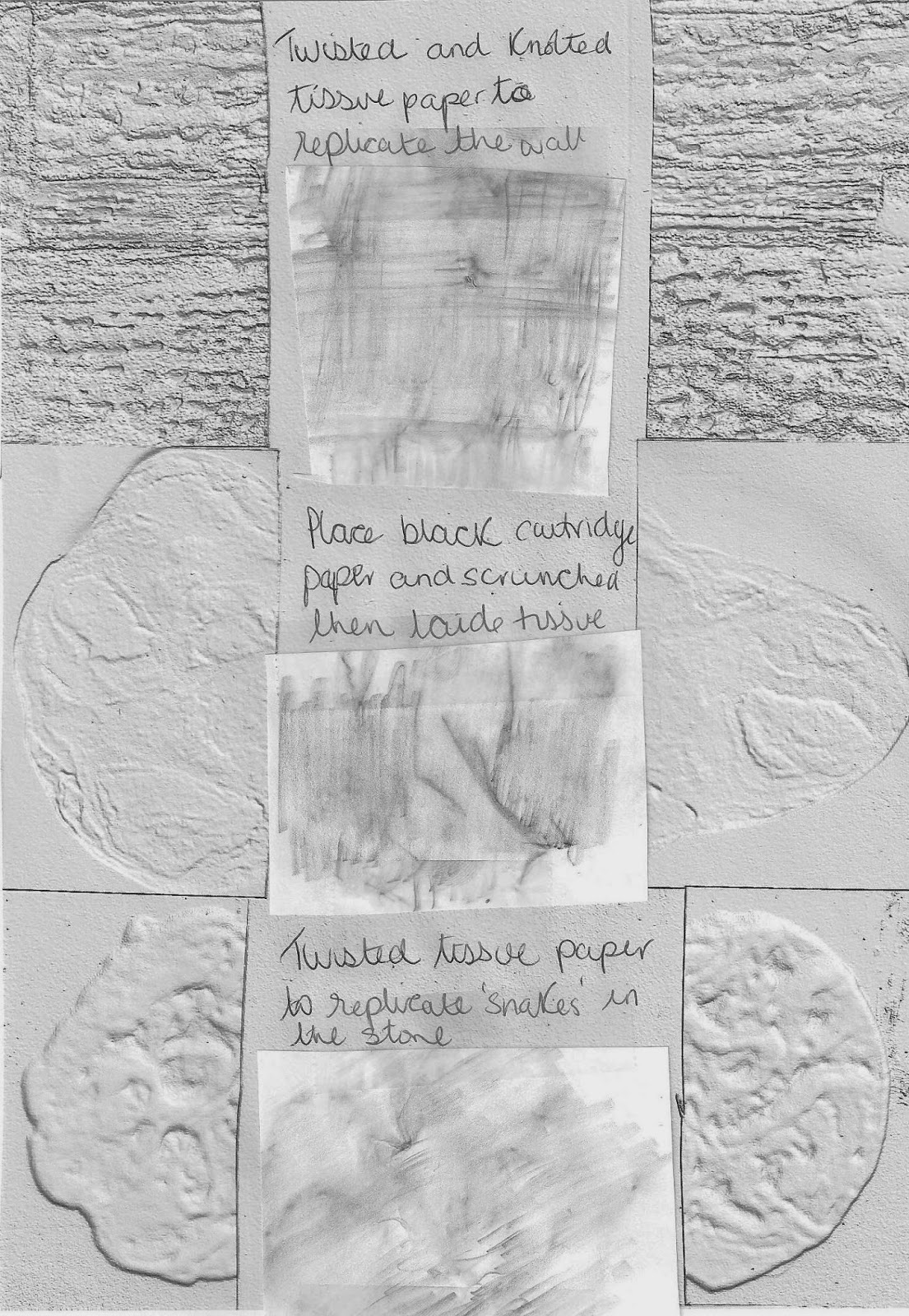

SELVEDGE, photo: strata image from previous chapter 5.3.2. Selvedge described in the dictionary as, 'as a woven edge that stops fraying' set me thinking. Taking the original strata photo for inspiration and then blowing it up the following observations were made. The selvedges proved not only interesting in how they were made but how they curled and when the material was torn away from the edge how the torn edges reacted against a firm edge.

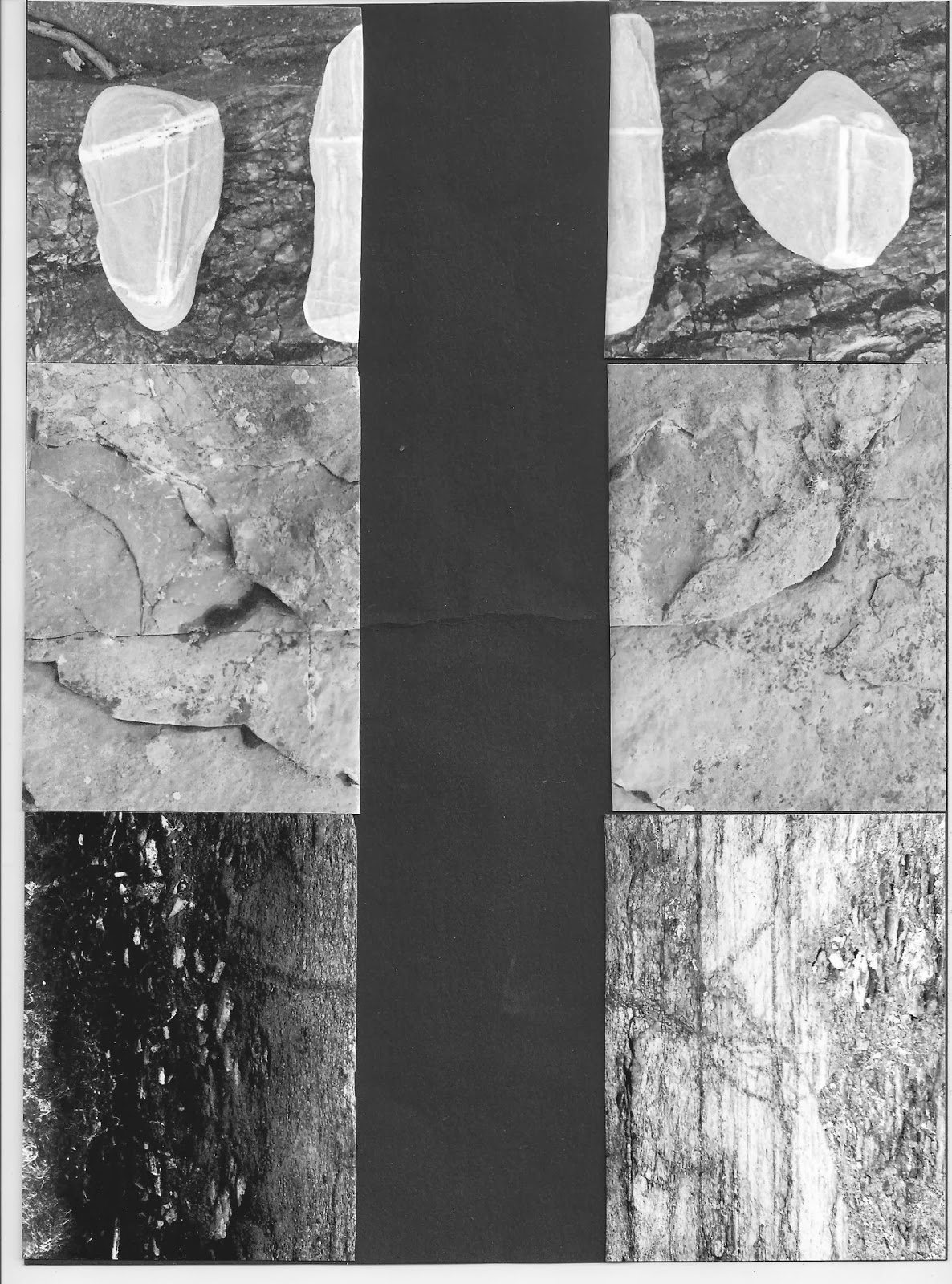

|

| Ref 5.4.2 |

Top item blow up of section of strata photo from 5.3.2

14 hole canvas selvedge

Cotton showing tenter hook detail

Torn edge formed a 'stepped' selvedge on silk

This fleece edge curled and again tenter hook holes can be seen

folded over this torn selvedge edge of silk

Elastic 'selvedge' and torn lace

This lace ribbon had two different 'selvedges' and again the tear proves interesting

|

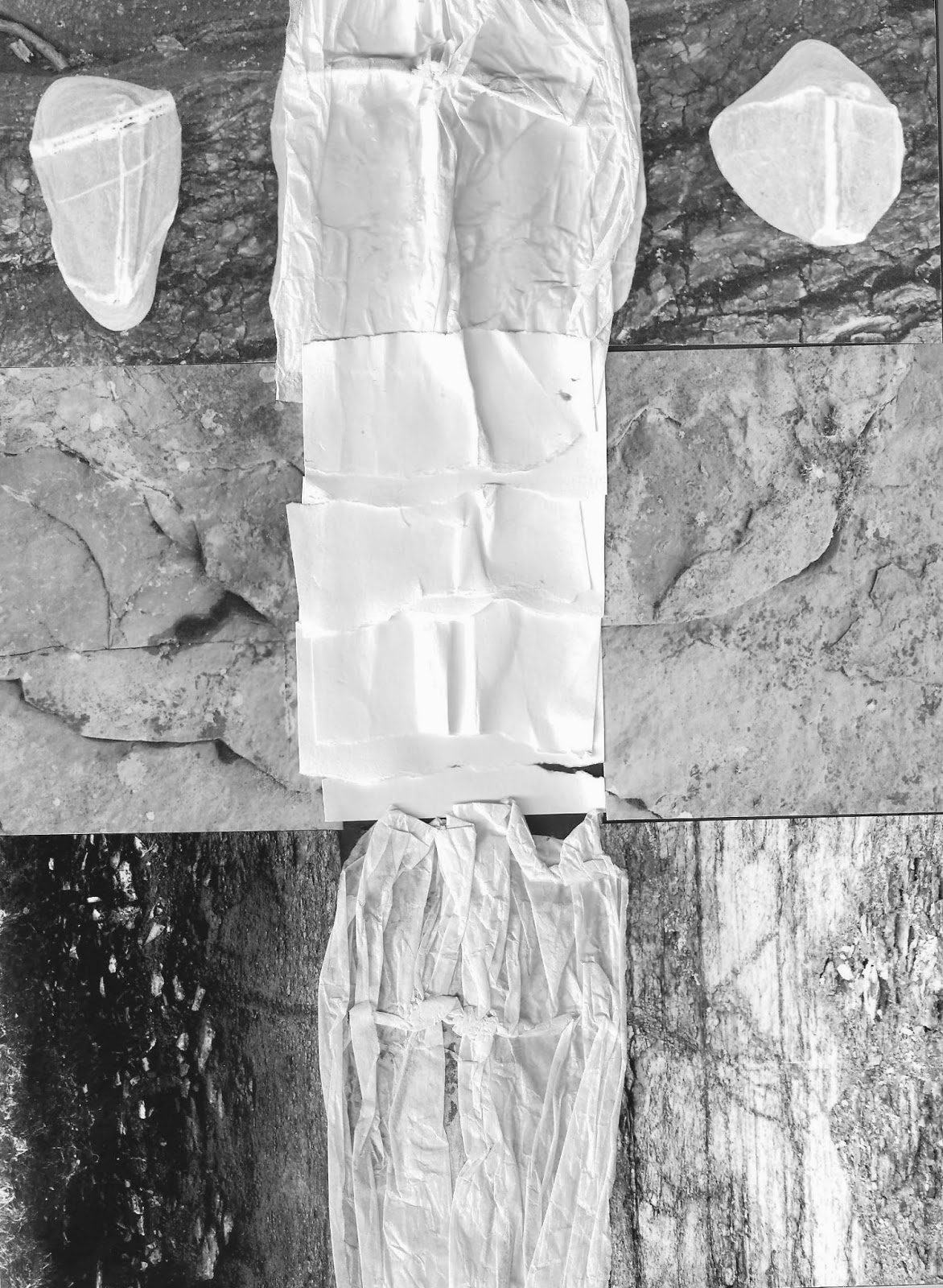

Ref 5.4.3

|

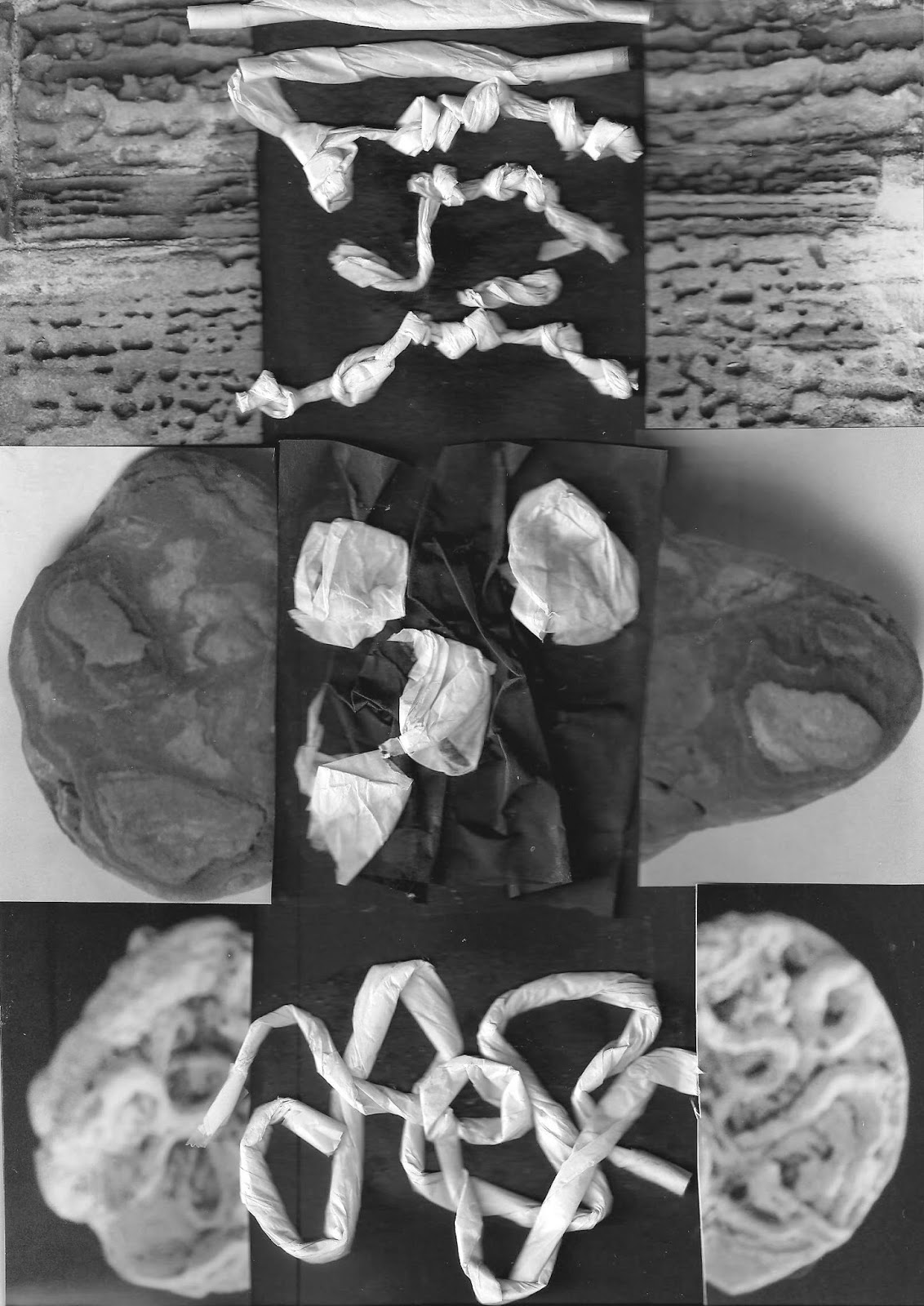

JAGGED, photo the rocks from Mull of Kintyre( ref 5.2.2) top right side

tear, fray, snip, pinked, vent:

A. Cotton poplin torn and opened

B. Linen frayed and snipped top edge, frayed and knotted bottom

C. Fleece straight snipped and twisted

D. Cotton angled snip and twisted

E. Two weights of cotton pinked and place over each other

F. Silk noil

|

| Ref 5.4.4 |

SOFTEN, photo: lichen stone from Broch of Gurness (ref 5.2.3) bottom right side. curve, scallop, twist, knot, gather

A. Nylon lace

B. Net twist

C. Net twist and knot

D. Fleece knotted

E. Cotton twist and loop

F. chenille wire curved

G. Linen cut curve and frayed

H. Cotton gathered on edge and in middle

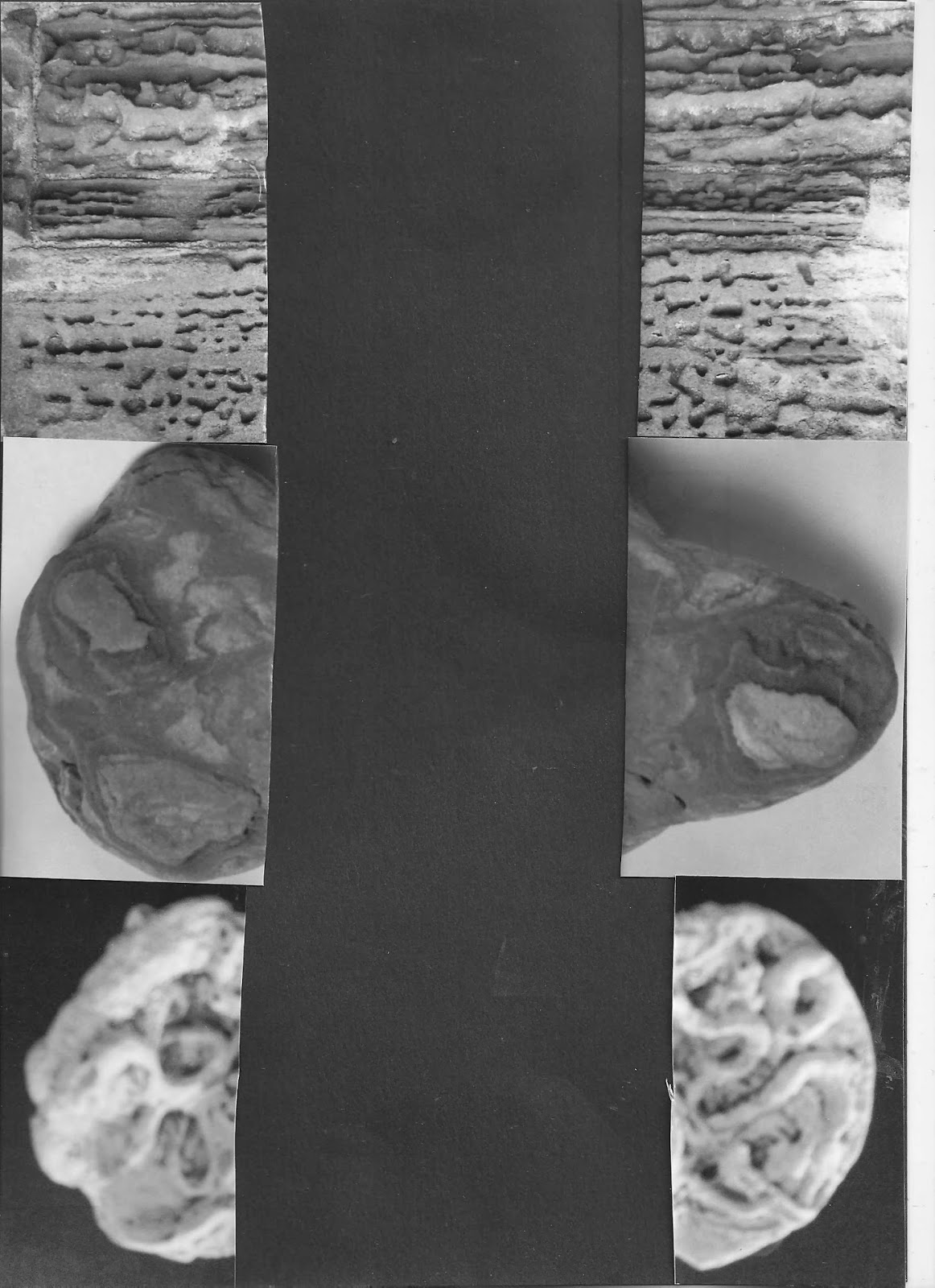

ERODE, photo: Arbroath Abbey wall, central detail.

|

| Ref 5.4.5 |

burn, sear, melt, hole, wear away

A. Silk

B. Lace

C. Cotton

D. cotton muslin

E. Face wipe, polyester and viscose

F. Nylon

G. Nylon lace

H. Sari

I. Nylon net

J. Tyvek

K. Nylon spot net

L. Nylon spandex

The heat tests were done with a two sizes of soldering irons and a candle. The soldering irons were easier to handle but the candle flame made it interesting to see what happened relatively quickly! Good caution in Module notes to have a water bucket close at hand. Slowly lowering fabric onto the flame proved more manageable than approaching from the side. The character of the face wipes, sample E, where amongst the most rewarding of the samples -soldering iron opened up fabric but didn't destroy the fibrous nature and the candle burn produced globules. Tyvek, sample J, an addictive performance with heat as it moves, melts and opens up into holes but the open stiff net , sample I, proved more manageable with the soldering iron. I only had a small piece of nylon spandex and pulled it onto a bias and soldered it in sample L.